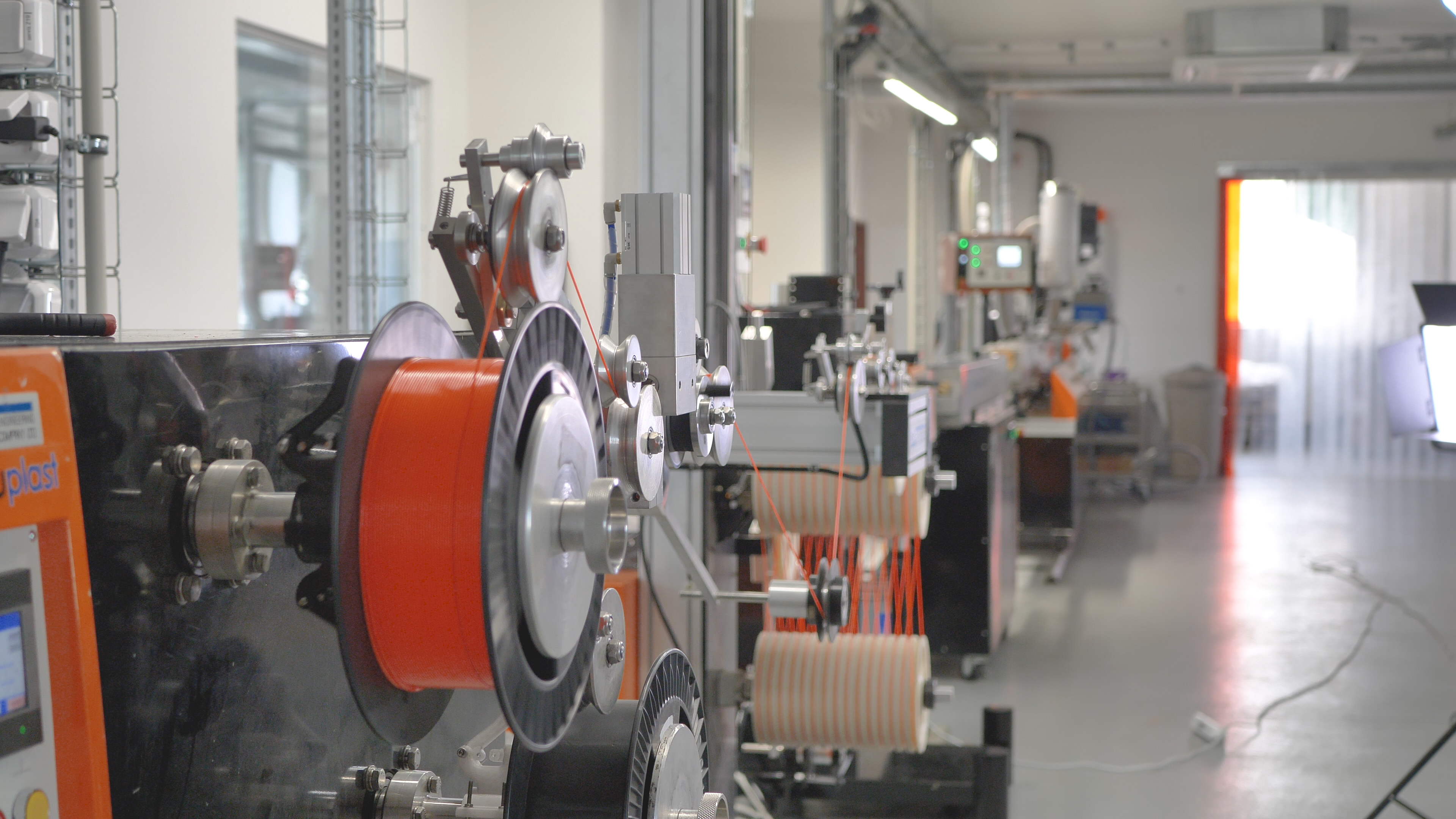

Manufactured In-House By Josef Prusa

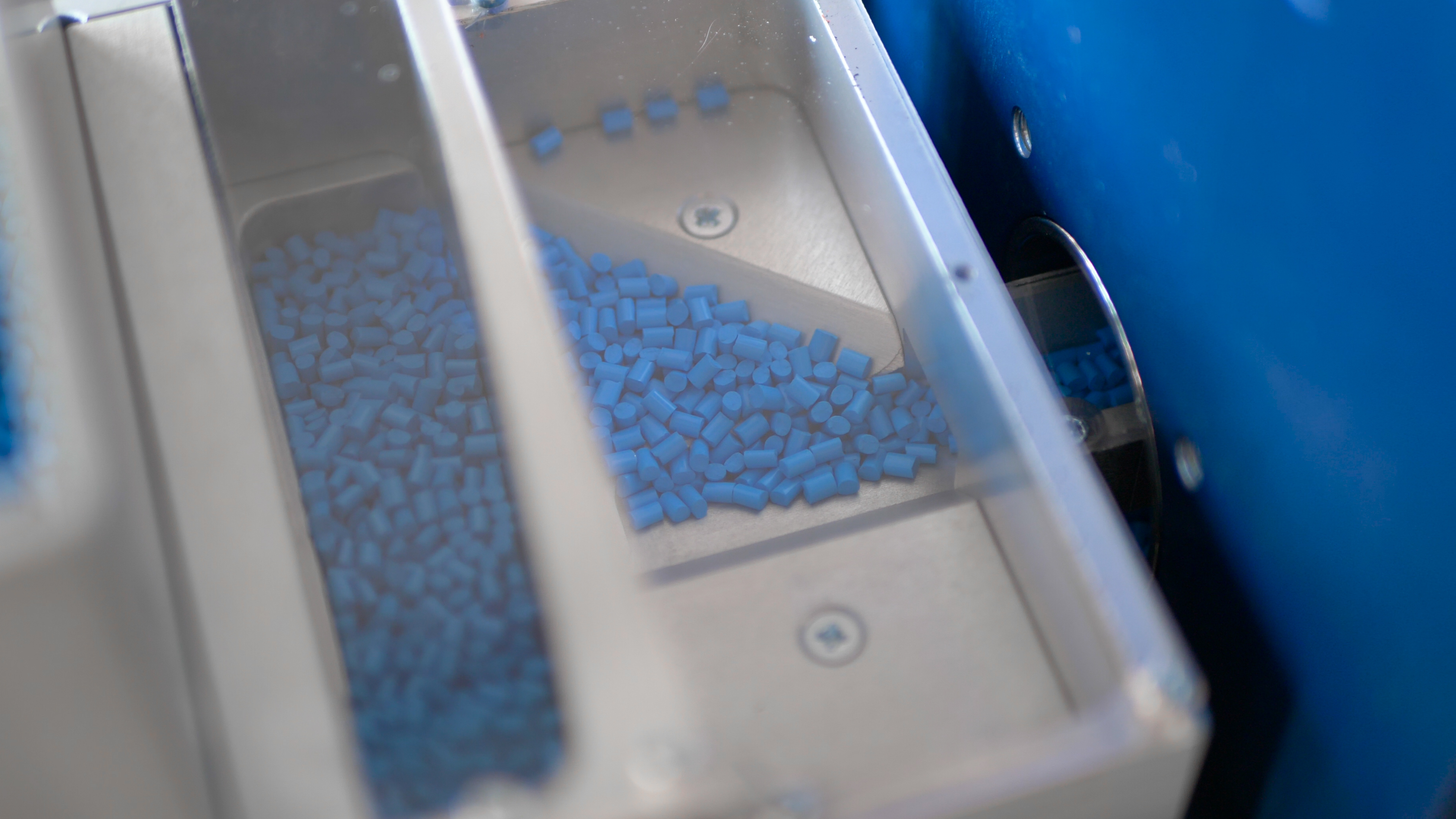

Premium-Grade Materials And Thorough Testing

The whole manufacturing process is closely monitored and tested – string diameter, color consistency, and mechanical properties – to make sure that every spool is perfect.

± 0.02 mm Manufacturing Guaranteed Precision

About PETG

PETG is a very tough material with good thermal resistance. Its use is universal but especially suitable for mechanical parts and both indoor and outdoor use. PETG has almost no warping, so printing large objects isn’t a problem. We use PETG to print parts for our printers!

PETG is one of our favorite materials for 3D printing. It’s almost as easy to print as PLA, but it can offer many mechanical properties that PLA prints just cannot achieve. The G in the acronym PETG stands for Glycol which is added during the manufacturing process. Glycol modifies the properties of PET, so that it’s easier to print, less brittle and clearer when printing with semi-transparent variants. PETG has low thermal expansion, so even when printing big objects, and without an enclosure, it rarely lifts from the bed and warps. In addition to that, PETG is ductile. It has a healthy amount of flex which can prevent parts from breaking under pressure.

Unlike PLA or ABS, PETG tends to ooze a bit and may leave strings of plastic on your print. You can fight this with increasing retraction and playing with hotend temperature, but if you use our filament presets in Prusa Slicer, we already did that for you and the amount of stringing is minimal. If you witness a tiny bit of stringing anyway, you can get rid of it by quickly blasting your finished prints with a heat gun.

If you can handle the oozing and strong adhesion, you’ll be left with a very durable print, that is considerably temperature resistant and usable for both indoor and outdoor use.

Printing Setup

| Nozzle | 250 °C |

| Heatbed | 70-90 °C |

Basic Attributes

ProsHigh temperature resistance

Easy to print

Low shrinking and warping

Simple to sand

Cons

Not suitable for tiny parts

Possibly of stringing

Poor bridging characteristics